Preventative Maintenance

A Classic Aston Martin is many things. Beautiful, powerful, elegant and timeless. It is also made from a lot of steel and aluminium which when left untreated will result in extensive corrosion and ultimately weakening of the main structure of the car. The problem with making an incredibly strong chassis out of a ferrous metal means that once the underbody protection breaks down, corrosion is the inevitable result and it is sadly time consuming and costly to repair.

Underbody protection will only last so long before the adverse road conditions and elements break down the thick rubberised protection and expose the now vulnerable steelwork to corrosive water and winter salt. Over time and left untreated this can lead to very in-depth and expensive repairs to reinstate the chassis and floors back to their original strength.

To help alleviate this from happening it requires both regular annual inspections to examine the degradation of the underbody protection and once identified, formulating a plan of action to remedy any issues. Dealing with any corrosion in its early stages is generally much more straightforward and may require only local repairs rather than major chassis refurbishment.

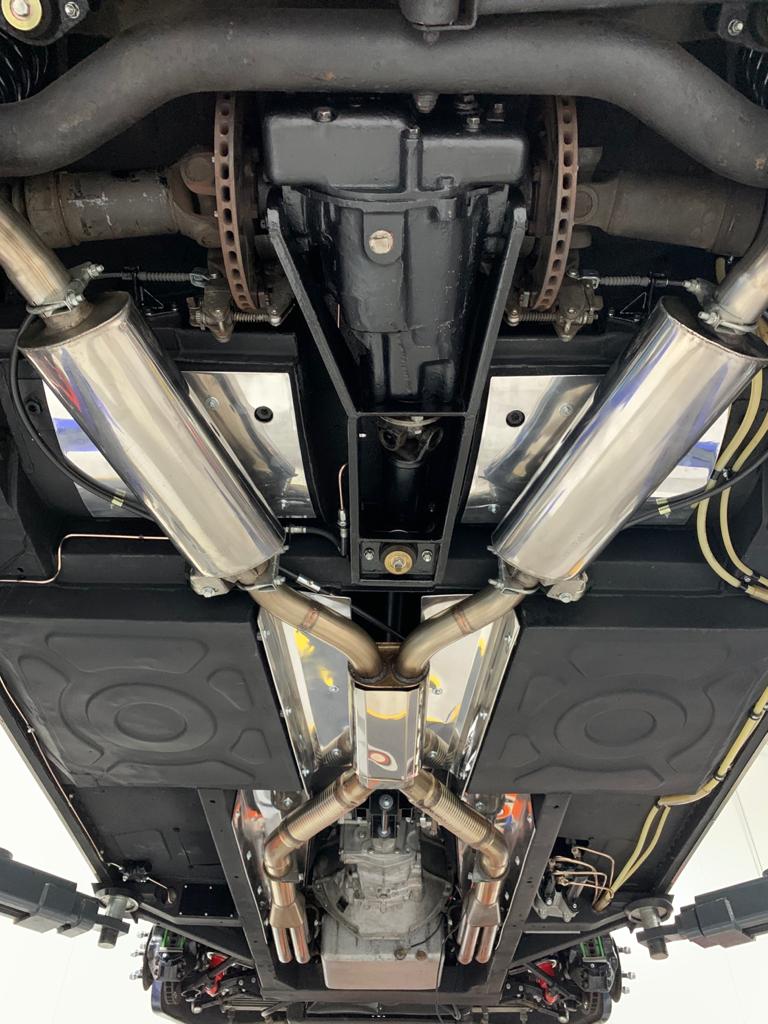

At Trinity Engineering we understand only too well how to preserve the integrity and originality of your Classic Aston Martin and therefore we have a process of firstly removing the original hardened and flaking protection back to bare metal. Then priming the exposed steel and aluminium with a zinc-based primer before ultimately coating the underside in two layers of the latest specification rubberised underbody compound. Finally, we will inject cavity wax into all box sections to starve the unprotected steel of oxygen and help alleviate further deterioration of the steelwork from the inside out.

The gallery of photographs shows a Trinity Engineering Preventative Maintenance program from start to finish and all the different processes involved in the preservation of a Classic Aston Martin for many years to come.

|

|

|

|

|

|

|

|

|

|

|

|